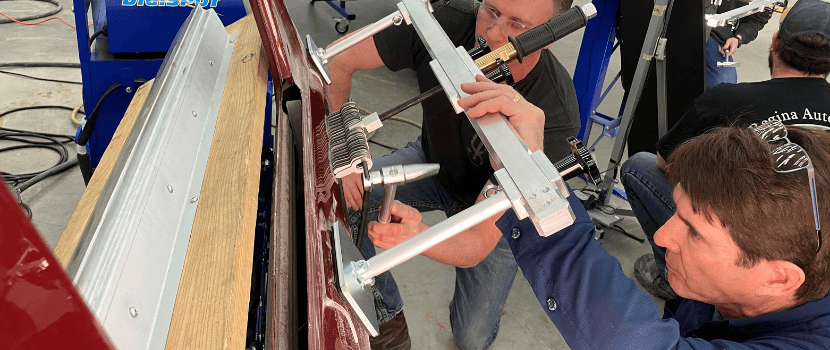

The work mix in body shops has been steadily changing and outer panel repairs now account for more than 60% of the total work in a shop. At the same time, significant advances in outer panel repair methods present a major opportunity for progressively minded repairers to embrace new ways of working to improve performance and create a competitive edge.

Saskatchewan Polytechnic realizes the unique challenges involved in implementing a broad training strategy. We also recognize that each auto body professional has unique professional development goals to increase their personal success in their careers. The following training provides employees with new skills to be more efficient to meet the needs of the auto body industry.

Students who complete the courses below will receive a certificate of achievement from Saskatchewan Polytechnic along with an accreditation as a BETAG Outer Panel Repair Specialist.

Start date and location

The program will be delivered to students through face-to-face practical components. The practical components of the training will take place through completion of shop-based activities.

When registration opens secure your spot and register early. Our course fills up quickly due to high demand.

Dates:

- March 16-20, 2026 (Saskatoon)

- April 13-17, 2026 (Saskatoon)

- May 11-15, 2026 (Saskatoon)

- June 8-12, 2026 (Saskatoon)

Courses

Step one: Course information

Day one

- Focuses on 'paint less' and 'push to paint' techniques for quickly and efficiently repairing small damage, using the T-Hotbox, glue pulling and knocking down techniques. The importance of using light properly, to analyze and repair damage is also covered during the first day.

Day two

- Builds on the knowledge and skills needed to straighten more complex, larger deformations by introducing the use of a bridge system and Speedline tabs together with a combination of the techniques learned on day one.

Day three

- Develop technicians’ skills to:

- Quickly and properly assess damage to steel outer panels and plan the repair.

- Efficiently straighten complex outer panel damage to near metal finish quality including damage thru bodylines; damage involving multiple bodylines; area damage (damage without a bodyline to stabilize the panel); and deep gouges.

Day four

- Increase technicians’ skills to prepare steel, aluminum, and plastic outer panel repairs for the refinishing process, in accordance with OEM repair procedures and quality standards.

Relevant to technicians of all experience levels, the knowledge and skills learned in this course will increase overall quality of repairs, reduce the risk of comebacks and improve efficiency during the repair process.

Step two: Course information

Day one

- Recap and assessed practical of small damage and medium panel.

Day two

- Medium panel repair - aluminum

- Increase technicians’ skills to repair medium sized damages on aluminum outer panels - starts with the material properties of aluminum and using light to identify the complete damage area and various zones within it. Using this as a foundation, the rest of the day focuses on a range of repair methods, including soft push, glue pulling and BETAG’s Alu T-hotbox to repair largely elastic deformations on aluminum panels.

Day three

- Medium panel repair – aluminum

- Increase technicians’ skills to repair medium sized damages on aluminum outer panels by building on the skills needed to straighten plastic deformations, using stud welding together with a combination of the techniques learned on the previous day.

Day four

- Advanced glue repair

- Increase technicians’ skills to repair medium sized damages on steel and aluminum outer panels with glue.

Relevant to technicians of all experience levels, this course develops the knowledge and skills needed to use glue (in isolation or in combination with other methods) to repair much larger areas of damage on steel and aluminum panels, often significantly reducing the refinish area and time.

Step three: Course information

Day one

- Recap and assessed practical of small damage and small damage repair level 2 (first half). Increase technicians’ skills to repair small sized damages on steel and aluminum outer panels. This course builds on the skills learned in the first small damage course, by introducing advanced small damage repair techniques, including the use of rods, picks, and levers.

Day two

- Small damage repair level 2 (second half) and recap and assessed practical of medium panel damage repair.

Day three and four

- Recap and assess practical of medium panel repair – aluminum and advanced glue repair.

Step four: Course information

Day one and two

- Glass repair and replacement

- Develop the knowledge and skills necessary for technicians to repair or replace glass in accordance with OEM repair procedures.

The course includes modules to develop technicians’ awareness of the various ADAS systems that can be affected, and the steps that need to be taken to research and implement associated OEM repair procedures.

This benefits the technician by enabling them to complete repairs properly with less waiting time; and enables collision centres to realize additional gross profit benefits by retaining some or all this type of work in house, instead of sub-letting it.

Day three

- Graded skills assessment for accreditation (small damage level 1 and 2, medium panel repair (steel).

Day four

- Graded skills assessment for accreditation (medium panel repair - aluminum) and plastic repair and restoration.

Registration

The cost for this 120-hour course is $13,500+GST. The course runs for four days each month for a total of 16 days.

Registration is on a first come, first served basis.

Contact us

Questions? Contact Tess Nakrayko by email at tess.nakrayko@saskpolytech.ca or by phone at 306-659-4038.