Jacob Wassermann competes in Paris in rowing seat designed and built at Saskatoon campus

Members of Sask Polytech’s Research, Additive Manufacturing and Prototyping (RAMP) team built the rowing seat used by Jacob Wassermann at the Paralympic Games in Paris. They followed the PR1 athlete’s races with bated breath. The competition was Wassermann’s second international meet, after earning a silver medal at the Continental Qualification Regatta in Brazil last spring.

A survivor of the Humboldt Broncos bus crash in 2018, Wassermann has found a new calling in para rowing. Wassermann knew very little about the sport before beginning training nearly two years ago.

“Being an athlete is a big part of who I am. The only similarities between hockey and rowing are that you need to work hard in both,” he says. “Para sport is so different because everyone is unique. Each athlete has specific needs, so the goal with building the seat was to create equipment tailored to help me perform at my best.”

The initial objective was to complete a custom rowing seat in time for the 2028 Paralympic Games in Los Angeles, but Wassermann’s success in Brazil accelerated the timeline. To help him make the most of his Paralympics debut, the RAMP team embarked on making their first ever para seat. “We treated the request like an applied research project,” explains Leon Lipoth, RAMP research chair for the Sustainability-Led Integrated Centres of Excellence (SLICE).

“Jacob had a really clear understanding of what he needed. As a PR1 athlete, he’s

doing all the work with his upper body. He needed a seat to better fit and support

him. His previous seats had friction points, so he attached pool noodles to them with

electrical tape as a remedy. We looked at other PR1 seats and at his wheelchair for

design inspiration to tailor a seat for his needs,” says Lipoth.

“Jacob had a really clear understanding of what he needed. As a PR1 athlete, he’s

doing all the work with his upper body. He needed a seat to better fit and support

him. His previous seats had friction points, so he attached pool noodles to them with

electrical tape as a remedy. We looked at other PR1 seats and at his wheelchair for

design inspiration to tailor a seat for his needs,” says Lipoth.

The custom-made seat changed training and improved the rowing experience.

“It was different with the new seat. It was lower and at a different angle. Going from something patched together to something custom made was an improvement,” Wassermann explains.

The researchers worked efficiently to ensure Wassermann's seat was ready before his flight to France. Lipoth enlisted additional help from Sask Polytech staff and from Braithwaite’s Upholstery to meet the deadline.

"I involved as many people as I needed and that turned out to be a lot of people. Jacob talked about how every para rower has a person to help them with their seat. I told him, ‘Well you have a whole team,’” Lipoth shares.

Wassermann notes, “They’re a really passionate group at Sask Polytech. They were pumped to get in there and I appreciated their enthusiasm in making something like this for the first time. When you have a passionate team, you know you’ll have a good product.”

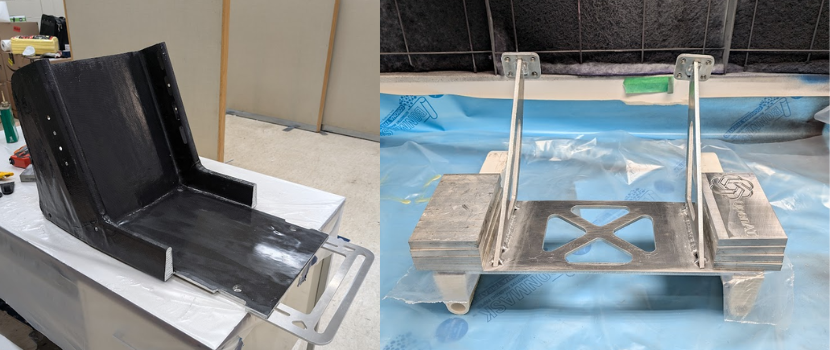

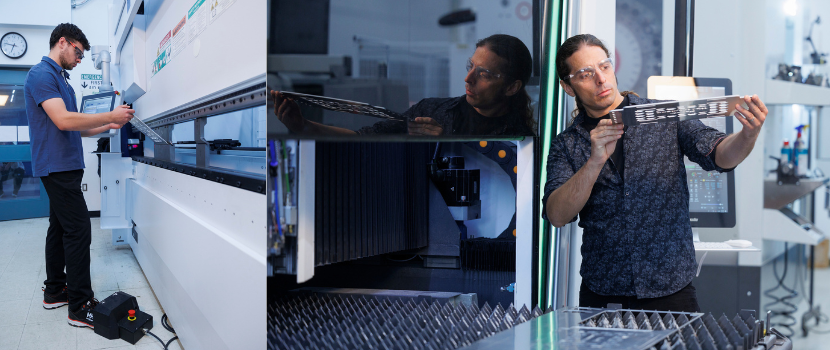

To ensure safety measures were followed, the RAMP team researched regulations on para rowing seats in competitions. Additionally, the arrival of two new pieces of equipment at the RAMP facility—a laser cutter and a metal bender—proved essential for fabricating the seat. Their arrival in late June left little wiggle room in the manufacturing timeline.

The first version of the seat was completed in mid-July, but there were challenges. It didn’t fit into the boat because of ribs around the edge of the vessel. The team cut down the seat to fit the width, and Wassermann requested that the seatback be lower. After modifications, the seat fit in the boat. August 1 was the first day of training with the new seat and Lipoth was on site for the installation and to make any adjustments.

“We were happy to put something in his hands that he was able to train and compete with. Jacob’s success has been fast and furious. It is rewarding to help,” he says.

Wassermann came ninth overall in the PR1 men’s single sculls and placed fourth in

the B final.

Wassermann came ninth overall in the PR1 men’s single sculls and placed fourth in

the B final.

Although Wassermann has the L.A. Paralympics in his sights, the 24-year-old university student is currently focused on balancing his studies and his training after a well-deserved break.

“The last six months have been a whirlwind with a lot of attention, interviews and a heavy workload. I’m very proud that I made it to the Paralympics,” he says. “Since getting back, I’ve been trying to relax. I’m taking the rest of the season off to feel refreshed and recover.”

“With my experience in Paris, I know what to expect now. I learned that it takes a lot of time and practice. Rowing is a hard mental game as much as it is a physical one. This seat was version one. Now we have a better understanding of what worked and what didn’t, so we’re going to work to make it even better for future competitions,” he says.

Adds Lipoth, “My message to Jacob is that we're ready to continue to help and support him. He has a team at Sask Polytech.”

RAMP is one of SLICE's state-of-the-art facilities in Sask Polytech's Innovative Manufacturing Centre. SLICE aims to advance sustainability in Saskatchewan and beyond through collaborative applied research for the benefit of our economy, environment, society, and future generations.

Learn more about applied research opportunities with Sask Polytech at saskpolytech.ca/slice and saskpolytech.ca/research.