Revving towards a sustainable future, Sask Polytech competes on the Indianapolis Motor Speedway in one of the world’s leading energy-efficiency competitions.

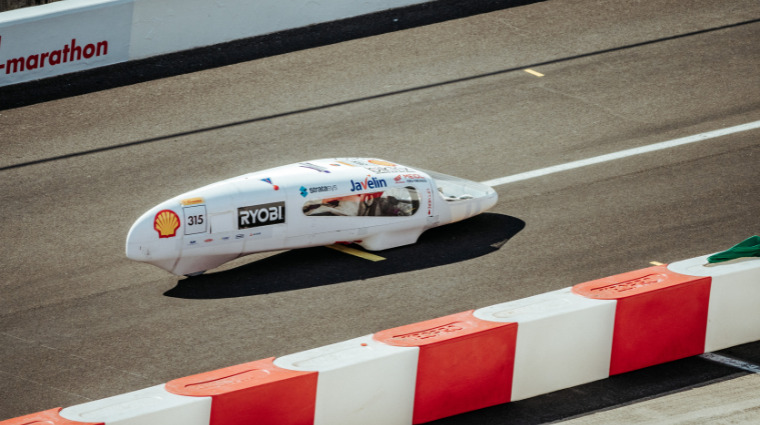

April 18, 2023 – Saskatchewan Polytechnic students are innovating for the future, racing towards the finish line with two energy efficient cars built out of recycled materials. The Sask Polytech urban concept car finished in first place and the prototype car finished in third place in their respective fuel economy categories at the Shell Eco-Marathon Americas Challenge at the Indianapolis Motor Speedway on April 16. The urban concept car also placed second in the Drivers World Championship regional competition, which qualifies Sask Polytech’s urban concept car and team to compete at the Shell Eco-marathon Drivers’ World Championship Grand Final in India this October.

Since September 2022 Sask Polytech students have been designing, building, refining and testing two vehicles for Shell Eco-Marathon Americas Challenge 2023 in the urban concept and prototype categories. With a result of 811 mpg us, Sask Polytech earned a first-place finish in the urban concept category. Sask Polytech earned a third-place finish in the prototype category, with a result of 292.8 mi/kWh per litre fuel efficiency.

“Congrats to our students on their first and third place finishes! We are incredibly proud that our students have had such a strong finish at the Shell Eco-marathon Americas competition,” says Dr. Larry Rosia, Sask Polytech president and CEO. “Our students are the only Canadian Team to qualify for the Drivers’ World Championship Grand Final in India. Our students’ performance is a testament to their dedication and hard work, and the dedication of our faculty, who provided guidance and support throughout the journey. These students are true innovators, taking on the challenges and opportunities of the future, showcasing their skills and talent on a global stage.”

“This year has been a luxury for the team, as we were able to continue to work on the two cars we entered into the 2022 competition – we didn’t have to start from scratch,” says Tim Muench, Design and Manufacturing Engineering Technology program head. “For the last eight months students have been making the systems better and building in reliability. We have also made some upgrades and are using more recyclable materials. The results have really paid off with first and third place finishes. I’m so proud of our team.”

The energy efficiency competition brought together over 60 student teams from across North and South America to push the boundaries of energy efficiency and innovation. The goal of the Shell Eco-marathon is for teams to drive and compete for the best energy efficiency result in their vehicle class and energy category. At the heart of this competition lies an age-old problem: how can we travel using as little energy as possible?

Sask Polytech students have worked hard to solve this problem. Since 2018 the team has taken inspiration from Saskatchewan's prairie culture, incorporating recycled carbon fibre hockey sticks into the frames for all eco-marathon cars. The urban concept car also has a 35cc ice auger engine with a custom fuel injection system and a steering wheel made of flax fibre. The body of urban concept car was 3D printed using recyclable materials. Special filament was used with a temperature triggered, active foaming technology to reduce the weight to one third of a traditional 3D printed part. A two-litre pop bottle is used to pressurize the fuel system.

“The composite made out of flax fibre for the steering wheel is new this year,” says Muench. “It’s a good secondary use for flax straw, which has to be burned to be destroyed. It doesn’t get more prairie than flax straw, ice augers and hockey sticks.”

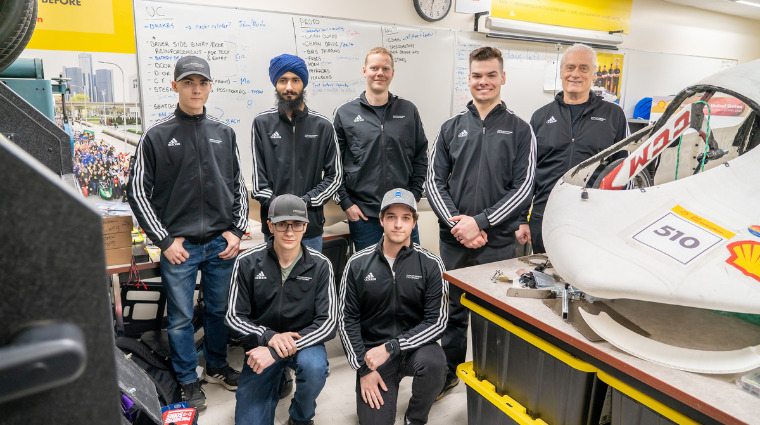

Under the direction of Muench and designated faculty advisor Andrew Baerg, Sask Polytech Mechanical Engineering Technology (MET), Design and Manufacturing Engineering Technology (DMET), Machinist, and Automotive Service Technician (AST) students have been working on the two energy efficient cars since September 2022.

“It’s super cool to be a part of Sask Polytech’s Eco Car team,” says Linden Herperger, a DMET student. “It’s a creative, innovative, collaborative environment. It’s amazing to know we built these cars from nothing. It’s surreal. Driving around a famous racetrack wasn’t previously on my bucket list. But in hindsight, it is now. It’s an incredible thing to do. I can’t wait for the Drivers’ World Championship Grand Final!”

The urban concept car is designed for city driving and considers comfort and space for luggage, along with fuel economy. This car could potentially be used as a future commuter car and must include two doors, four wheels, full lighting, horn, brake functions and a windshield wiper. It’s a challenge for teams to create maximum energy efficiency with these added mandatory elements included.

The prototype car is an ultra-efficient, lightweight vehicle designed for fuel economy. This vehicle type has the potential to reach record breaking energy efficiency in this category. Working within the rules, teams consider how to make their car as streamlined and aerodynamic as possible. Sask Polytech’s prototype car is electric, with a 3D printed body and is quite small to reduce aerodynamic drag and rolling resistance.

Sask Polytech has been competing in the Shell Eco-Marathon since 2017.

Shell Eco-marathon is one of the world’s leading student engineering competitions focused on energy optimisation where teams are asked to design, build and drive some of the world’s most energy-efficient vehicles. Teams drive and compete for the best energy efficiency result in their vehicle class and energy category against teams from other academic institutions.

The top four winning teams from the regional competitions in Asia, the Americas and Europe will travel to compete in the Shell Eco-marathon Drivers’ World Championship Grand Final. The Grand Final will provide an excellent opportunity to showcase Sask Polytech and its exceptional students on the world stage.