While 3D printing offers a way to translate ideas quickly from a computer screen to tangible, durable products, it’s tough to take the plunge and invest in expensive equipment whose potential is unknown.

“Before companies make that expensive purchase, we have the ability to work with them to ensure that they know what can be achieved. It helps them make an informed decision before they invest,” said Tim Muench.

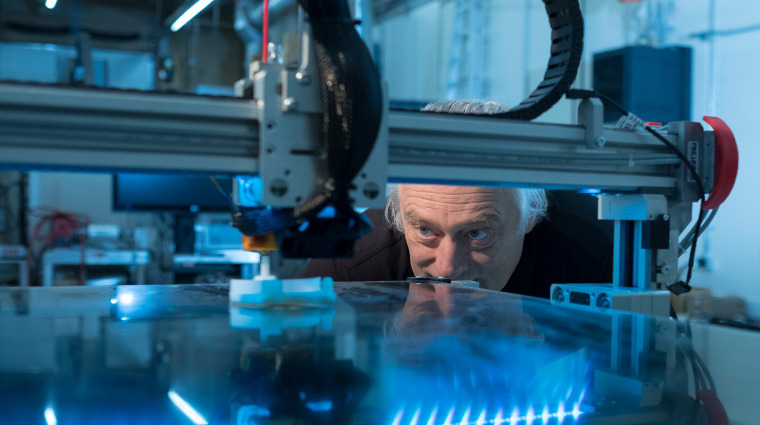

Muench is program head of Sask Polytech’s Mechanical Engineering Technology and Design and Manufacturing Engineering Technology programs and senior researcher for the Research, Additive Manufacturing and Prototyping (RAMP) facility at the Innovative Manufacturing Centre (IMC) at the Saskatoon campus. He explained RAMP machines can print with various types of plastics and composites. The RAMP facility is the most advanced additive manufacturing facility in Saskatchewan. It contains the only metal 3D printer in the province, as well as a waterjet cutter and a portable 3D scanner.

RAMP offers industry, including small and medium sized enterprises, the ability to bring in ideas created on their computers, then test them in the real world without extensive machining or creating special dies or molds.

“Rather than having to machine it, often times they can make a carbon fibre part or something similar that will get them the results they need,” Muench said.

Products made from 3D printers can be extremely durable. For example, the metal printer produced “fingers” for a robot gripper on a manufacturing line to replace less durable original plastic parts and the carbon fibre printer quickly created an adapter to mate an electric motor to a machine, helping a company meet an important deadline.

“The output of these machines can be used to fully test prototypes or as production components,” Muench said.

“Sask Polytech’s RAMP facility helps employers solve today’s complex business challenges through applied research,” says Dr. Susan Blum, associate vice-president, Applied Research. “Using state-of-the-art facilities, equipment and faculty expertise Sask Polytech delivers solutions and helps employers to capture new opportunities.”

Since its opening two years ago, the RAMP facility has undertaken several industry applied research projects, one of them with Environmental Instruments Canada. The company produces radiation measurement devices for the uranium industry. However, its latest product was developed for homeland security markets and needed to be rushed to production. With the help of Sask Polytech’s RAMP facility, the shell and over-mold for the Environmental Instruments Canada device were 3D printed on a multi-material 3D printer. The process was very successful and Sask Polytech printed the initial production run of the new instrument. Additional research is now being done to improve the durability and ergonomics of the instrument.

“Contact us today to start a project,” says Blum. “Sask Polytech applied research partners may receive government funding, through organizations such as the National Research Council of Canada and Natural Sciences and Engineering Research Council of Canada, to assist in covering the costs for their research projects.”

Published October 2020.